OZgreen69

Well-known member

Hello,

I would like to show you what I am doing at the moment.

Fan of historic car racing, I am building/assembling/modifying, a 69 convertible to do just that here in Australia.

The rules of the group that the car will be into, are quite restrictive to keep the spirit of club racing alive ( Yeah right !! )

For example, no alloy heads ,or original gear box only, interior trim and a passenger seat must be retained , original kind of suspension . Well, all done to slow you spending too much ( Yeah right !! )

So I have been collecting bits and pieces along the way like :

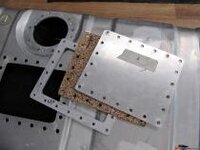

A 69 coupe who was going to be a race car in 2003 for historic racing as well, but instead to be pushed unfinished in a dark corner of a workshop and left there until last year when I bought it as a rolling chassis.

As the frame as been prepared in the Chevrolet Power Book fashion, I thought about reusing it for my race car.

The previous owner modified it using few Guldstrand parts.

Solid pucks for the rear cross member and adjustable toe system for the trailing arm and more....

I would like to show you what I am doing at the moment.

Fan of historic car racing, I am building/assembling/modifying, a 69 convertible to do just that here in Australia.

The rules of the group that the car will be into, are quite restrictive to keep the spirit of club racing alive ( Yeah right !! )

For example, no alloy heads ,or original gear box only, interior trim and a passenger seat must be retained , original kind of suspension . Well, all done to slow you spending too much ( Yeah right !! )

So I have been collecting bits and pieces along the way like :

A 69 coupe who was going to be a race car in 2003 for historic racing as well, but instead to be pushed unfinished in a dark corner of a workshop and left there until last year when I bought it as a rolling chassis.

As the frame as been prepared in the Chevrolet Power Book fashion, I thought about reusing it for my race car.

The previous owner modified it using few Guldstrand parts.

Solid pucks for the rear cross member and adjustable toe system for the trailing arm and more....

Last edited: