the curves on the coupe catch my eye every time I look at it. the weather is getting nice and i am finding my self drifting to the garage, a few non related MG tasks need to be taken care of and then its MGA time to finish adjusting the door latchs and put the front bumper on.

heres one of the projects scratched off the list.

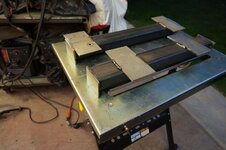

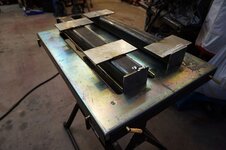

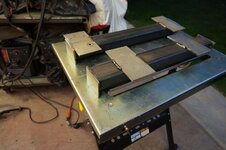

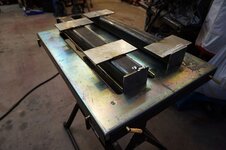

the corvette has a space age frame under it and it requires crossbeam adapters to hold the alloy frame properly...of course it does, this is for under the rear axle and the front cross member. well I have the need for some of these and the HF cross beam adapters that i eyeballed i would need to modify to fit the corette and two would cost me $70 or $80. I can buy the steel for about $27. so i have been looking at pictures on line and measuring under the car and asking a couple C5 guys questions about theres and this is what i came up with...

so here we go, I bought 2x3x1/4 rectangular tubing , and i had 1/4 plate laying around, the pads are 3 5/8 x 6 3/4 and the end caps hang down 1/2", these weigh about 20# and i have not put a jack shaft on, i am going to try just resting on my jack saddle

took about 45 minutes to cut everything with a cutoff wheel and about an hour to tack it up

i am going to do a full mock up with more then tack welds but less then full seams and will test it. i think i will add gussets to the pads sides just because i can....

capped ends so the jacks dont slip out

and they also fit the smaller jack stands

and yes these will get up pretty high