bobs77vet

Well-known member

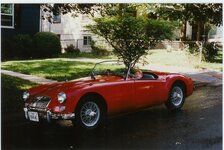

something new has found its way in the garage....follow along as we eat the elephant one bite at a time....hasnt run in over 27 yrs....heres the deal we bought it from a 79 yr old gentleman who bought the car in 1985 from a neighbors yard, he had restored one in 1965 and was going to restore this one but never got around to it....he did buy new bumpers, leather seat kit, all new rear and front glass, complete carpet set, deluxe panel set, headliner and complete rubber kit all of which is in good shape and it came with an extra MGA transmission and extra Triumph spitfire: engine, trans and set of seats...

work done to date....shovelled out crap from car, hosed down interior and exterior, pulled out center wooden floors,vaccumed car,oild windows and made them crank up and down, took out spark plugs and put 4ozs of auto trans fluid in each cylinder. oiled up valve train.....the oil in engine is clean and the oil in trans is clean, this is a good sign.... also unpacked all boxes of parts and they all look good the interior panel kit and upholstery looks fine....waiting for a sunny day to air it all out.

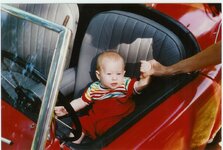

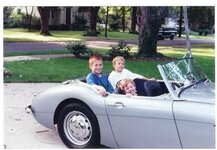

the accomplices.....

[/QUOTE]

[/QUOTE]

work done to date....shovelled out crap from car, hosed down interior and exterior, pulled out center wooden floors,vaccumed car,oild windows and made them crank up and down, took out spark plugs and put 4ozs of auto trans fluid in each cylinder. oiled up valve train.....the oil in engine is clean and the oil in trans is clean, this is a good sign.... also unpacked all boxes of parts and they all look good the interior panel kit and upholstery looks fine....waiting for a sunny day to air it all out.

the accomplices.....

[/QUOTE]

[/QUOTE]

Last edited: