You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1958 MGA Coupe

- Thread starter bobs77vet

- Start date

Sam Cogley

Well-known member

Repop is $12, I think I'd just replace it. http://www.northwestimportparts.com/MGB-Windshield-washer-bottle-62-72-d1437.aspx

Printable replacement decal: http://mgaguru.com/mgtech/accessories/at105c.htm

Printable replacement decal: http://mgaguru.com/mgtech/accessories/at105c.htm

bobs77vet

Well-known member

Repop is $12, I think I'd just replace it. http://www.northwestimportparts.com/MGB-Windshield-washer-bottle-62-72-d1437.aspx

Printable replacement decal: http://mgaguru.com/mgtech/accessories/at105c.htm

the original ones with the small top are N/A. ones with Larger tops are not much more then that....I guess I will clean it as best I can and then live with it until it bothers me into action. maybe better yet have that be a gift from the kids since my pusher for the water squirter is DOA.

Last edited:

bobs77vet

Well-known member

strictly hypothetically speaking.......if the boss isn't home is their a rule against wet sanding in the kitchen sink?

400 grit paper using dish washer detergent as the lubricant.

i can see getting one of those Mr clean eraser pads and doing this wet i bet i could even buff it with some polishing compound

i think it needs one more time with a really fine sand paper maybe 800

400 grit paper using dish washer detergent as the lubricant.

i can see getting one of those Mr clean eraser pads and doing this wet i bet i could even buff it with some polishing compound

i think it needs one more time with a really fine sand paper maybe 800

bobs77vet

Well-known member

bobs77vet

Well-known member

picked the carpet and thats on the way

now to the heater valve

and to the heater box control

clean the contacts

test with ohm meter after cleaning contacts and sanding bullets

now to the magic.....spray clear, if you had told me just cleaning and spraying with clear woud do this i would have not believed you

now to the heater valve

and to the heater box control

clean the contacts

test with ohm meter after cleaning contacts and sanding bullets

now to the magic.....spray clear, if you had told me just cleaning and spraying with clear woud do this i would have not believed you

bobs77vet

Well-known member

thanks guys

well i have been putting this off.....i really like the weldwood HHR glue and i decided to take down the headliner insulation and reglue . that was a PITA

and done

i used the heavy viscosity sprayer on this it was a PITA

then cleaned the headliner bows with steel wool and cleaned it with degreaser so it will slip through the head liner loops. when you got it lined up just right it slips right in.

i still have to figure out how to slip the headliner down over the screws but i will let it relax to its new position over night before i futz with it any more.

and i remembered i had a new knob for this

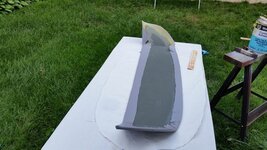

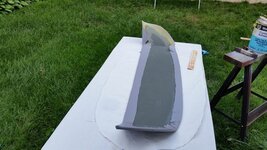

i have been thinking about lowering the body back down and i think i can use the coupe top as the support for using an engine lift and picking it up

i can even use the lip as a centering device so the board doesn't slide

well i have been putting this off.....i really like the weldwood HHR glue and i decided to take down the headliner insulation and reglue . that was a PITA

and done

i used the heavy viscosity sprayer on this it was a PITA

then cleaned the headliner bows with steel wool and cleaned it with degreaser so it will slip through the head liner loops. when you got it lined up just right it slips right in.

i still have to figure out how to slip the headliner down over the screws but i will let it relax to its new position over night before i futz with it any more.

and i remembered i had a new knob for this

i have been thinking about lowering the body back down and i think i can use the coupe top as the support for using an engine lift and picking it up

i can even use the lip as a centering device so the board doesn't slide

Last edited:

SuperBuickGuy

Well-known member

I had to use a steamer to get the last of the wrinkles out of a headliner that looked like yours .... steam really is your friend, that and many cuss words.

bobs77vet

Well-known member

its so freaking hot and steamy here it may relax on its own

this is also in a parallel thread for searching purposes for the next guy/gal

http://www.mgexp.com/phorum/read.php?2,3209648,3275056#msg-3275056

so i found a previous thread

http://www.mgexp.com/phorum/read.php?2,2056993,3275038,page=2#msg-3275038

and read it and asked a few questions and John Larsen helped me through the process, my top was different then one that Randy used in Barneys photos/write up and my loops were much longer and i could not figure at first the process to use.

but the answers and photos and sleeping on helped me sort it out.....interior work is not my strong suit

so heres the drill...

heres the over hang the bow is inside

this the idea

its been sitting in a box for 35 years.....

it can have over night to get use to a new shape

and now to buy 12 feet of 1" binder clips.....

this is also in a parallel thread for searching purposes for the next guy/gal

http://www.mgexp.com/phorum/read.php?2,3209648,3275056#msg-3275056

so i found a previous thread

http://www.mgexp.com/phorum/read.php?2,2056993,3275038,page=2#msg-3275038

and read it and asked a few questions and John Larsen helped me through the process, my top was different then one that Randy used in Barneys photos/write up and my loops were much longer and i could not figure at first the process to use.

but the answers and photos and sleeping on helped me sort it out.....interior work is not my strong suit

so heres the drill...

heres the over hang the bow is inside

this the idea

its been sitting in a box for 35 years.....

it can have over night to get use to a new shape

and now to buy 12 feet of 1" binder clips.....

Last edited:

bobs77vet

Well-known member

and back to rear parcel shelf....paper template to cardboard template to 18 ga steel to trial fit

and lets see if i have enough material

to cardboard and more trial fits

to template

to straight sheet

not everything needs a fancy brake

remember the parcel shelf frame i made i have one left (if any one needs it send me PM) so it gives me a fit gauge

i have to think about what to do here its almost like the shelf was suppose to be 3/8 thick, i have seen a sturdy foam for interior panels i may have to look at that again to put on top of the `18 ga

and lets see if i have enough material

to cardboard and more trial fits

to template

to straight sheet

not everything needs a fancy brake

remember the parcel shelf frame i made i have one left (if any one needs it send me PM) so it gives me a fit gauge

i have to think about what to do here its almost like the shelf was suppose to be 3/8 thick, i have seen a sturdy foam for interior panels i may have to look at that again to put on top of the `18 ga

bobs77vet

Well-known member

so I loosened the bows on one side and only cut from the bow loop the amount of the red body color showing for the bow and then moved to the other side. and did the same... then pulled the fabric down to the door lip. Jim Cheatham was gracious enough to cut the door surround trim and windshield headliner trim piece. so i need to make a trip south to pick those up this week. I still need to get the binder clips too finish the stretch. no reason to push this let nature and heat relax the fabric.

Sam Cogley

Well-known member

Just watched the "Wheeler Dealers" MGA episode last night. They're definitely cool little cars, and they got a pretty penny for theirs when it was done.

bobs77vet

Well-known member

yeah they do in an episode what takes us months...although I do like the show.....Ed Chinas tools have gotten better over the years.

I think I figured out why I have this gap

this is how the parcel shelf frame is lining up with the bottom of the window panel

this is an original parcel shelf frame lined up with the bottom of the window panel (from DanielR)

and that's why I have this gap, its pretty clear to me that the bracket tab got pushed down on the ends probably from someone leaning on it as leverage to pull a battery out. should be an easy fix to push the tabs more up right

I think I figured out why I have this gap

this is how the parcel shelf frame is lining up with the bottom of the window panel

this is an original parcel shelf frame lined up with the bottom of the window panel (from DanielR)

and that's why I have this gap, its pretty clear to me that the bracket tab got pushed down on the ends probably from someone leaning on it as leverage to pull a battery out. should be an easy fix to push the tabs more up right

Sam Cogley

Well-known member

yeah they do in an episode what takes us months...although I do like the show.....Ed Chinas tools have gotten better over the years.

Among the things I really like about the show is the lack of time-wasting "shop banter" stupidity that most of the US shows engage in, and the fact that Edd is very up-front about how long things take and that the work is compressed to fit in an episode. I also like the lack of intrusive sponsorship deals that most of the US shows engage in. I want to see someone working on a car, not spend 1/3 of the running time while the host engages in advertising. Even the tool brands (Teng in the UK, mostly Craftsman in the US) are damned near impossible to spot on-screen, and only get a small note in the end credits. One exception was in the MGA episode (I think) when Edd was using a specialty tool with a very large and impossible to hide Snap-On logo. On the other hand, the lack of a deal with sponsorship banners all over the shop means that if he needs a tool from Snap-On, he can just go ahead and use it.

Mike wouldn't have touched your coupe with a 50-ft pole. When he was looking for an MGA, he talked about the notorious rust problems and that they wouldn't make any money on a car that required more than minimal rust repairs.

Last edited:

bobs77vet

Well-known member

4 years later and I sometimes wonder what was I thinking.....although I do like the journey, but i dont need a another trip any time soon thats for sure

1000 binder clips later....

funny thing is you cant see those stretch marks with out the flash....looks like i found a trick to see how i am doing and no more complaining about Va heat and humidity...its actually helping me once in my lifetime

1000 binder clips later....

funny thing is you cant see those stretch marks with out the flash....looks like i found a trick to see how i am doing and no more complaining about Va heat and humidity...its actually helping me once in my lifetime

bobs77vet

Well-known member

bobs77vet

Well-known member

lets wrap up the parcel shelf as much as we can

move the rear parcel shelf frame so the bottom is where its suppose to be and drill a hole for a fastener

repeat other side

cut the panel to size to take up the gap

close fit on both sides with the same panel flipped over

when the 1/8 Luan is doubled up there is no gap

prime the steel

so the plan is use the steel as the supporting structure and get some 1/4" water proof panel board or maybe even masonite and glue it to the steel and then glue the vinyl to both of them.....the angle where the shelf drops down has no supporting piece so this is my way of dealing with it.

move the rear parcel shelf frame so the bottom is where its suppose to be and drill a hole for a fastener

repeat other side

cut the panel to size to take up the gap

close fit on both sides with the same panel flipped over

when the 1/8 Luan is doubled up there is no gap

prime the steel

so the plan is use the steel as the supporting structure and get some 1/4" water proof panel board or maybe even masonite and glue it to the steel and then glue the vinyl to both of them.....the angle where the shelf drops down has no supporting piece so this is my way of dealing with it.

Last edited:

bobs77vet

Well-known member

time to finish the parcel shelf.....dont really know how to do this smoothly so i am just doing it.....1/4 panel board

this was 5 hours of constant work

this is where we start the panel has been primed and dryed over night

fit the panel, use tape as a spacing tool off the back bend and make 5 holes for the top, i have decided to use #6 finishing screws through out the coupe....my #4 screws are loose in the existing holes so i am just going up one size. my original screws are an inbetween size of the now #4 and #6. any way decision made...too hard to find the original holes in the boot

the panel board is glued to the sheet steel

beveled edges sanded and puddyed up with 2 part glazing puddy

while i cut the material

just do it.....what could possibly go wrong? just paint up the panel and vinyl

and then pick up the vinyl to the panel so theres no wrinkles

flip it over and work on the edges

and just work your way around it

and done

and some clamps to compress the seams

this was 5 hours of constant work

this is where we start the panel has been primed and dryed over night

fit the panel, use tape as a spacing tool off the back bend and make 5 holes for the top, i have decided to use #6 finishing screws through out the coupe....my #4 screws are loose in the existing holes so i am just going up one size. my original screws are an inbetween size of the now #4 and #6. any way decision made...too hard to find the original holes in the boot

the panel board is glued to the sheet steel

beveled edges sanded and puddyed up with 2 part glazing puddy

while i cut the material

just do it.....what could possibly go wrong? just paint up the panel and vinyl

and then pick up the vinyl to the panel so theres no wrinkles

flip it over and work on the edges

and just work your way around it

and done

and some clamps to compress the seams

Last edited: