Sharkey1807

Well-known member

Hi Together,

lately all went a bit slower.

Some good reasons and some not so good.

So this update is not pretty new.

The electric fans came in and Steve assembled them at the end of july.

All went pretty smooth and easy in case of the assembly.

But before the radiator needed some care.

Easy installation with some kind of straps:

The inspection of the front brakes and rotors let make only one decission...

But see yourself.

Worn out Rotor:

Damaged bearings from burned grease:

Root cause was a incorrect thightening:

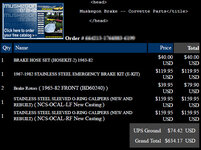

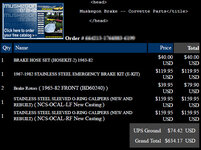

So a order by Muskegon Brakes was done:

Stainless calipers with o-rings:

And while the pencil was sharp i ordered also a complet stainless Parking brake kit:

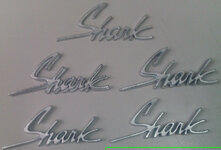

And to behold all sweet and nice:

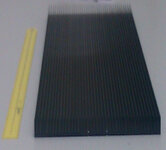

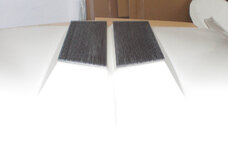

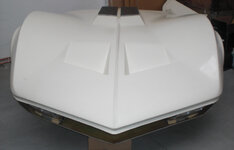

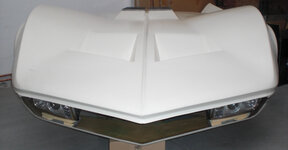

Also for the outside cosmetics i found a source.

A heater profil out of black anodized aluminum.

Ordered today 2 pieces and a colleague will cut them to size.

Then they get machined on top, front and rear and afterwards polished.

Finally a good coat of clear.

The ordered size is 200mm wide, 15mm high (machined down to 10mm) and 620mm long.

They will come on top of the hood slats.

The price is with 29 Euro per piece pretty convenient.

Greetings

Robert

lately all went a bit slower.

Some good reasons and some not so good.

So this update is not pretty new.

The electric fans came in and Steve assembled them at the end of july.

All went pretty smooth and easy in case of the assembly.

But before the radiator needed some care.

Easy installation with some kind of straps:

The inspection of the front brakes and rotors let make only one decission...

But see yourself.

Worn out Rotor:

Damaged bearings from burned grease:

Root cause was a incorrect thightening:

So a order by Muskegon Brakes was done:

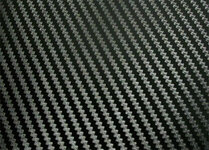

Stainless calipers with o-rings:

And while the pencil was sharp i ordered also a complet stainless Parking brake kit:

And to behold all sweet and nice:

Also for the outside cosmetics i found a source.

A heater profil out of black anodized aluminum.

Ordered today 2 pieces and a colleague will cut them to size.

Then they get machined on top, front and rear and afterwards polished.

Finally a good coat of clear.

The ordered size is 200mm wide, 15mm high (machined down to 10mm) and 620mm long.

They will come on top of the hood slats.

The price is with 29 Euro per piece pretty convenient.

Greetings

Robert