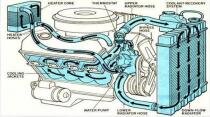

I have an Edelbrock 8853 water pump. This is a reverse rotation serpentine drive pump made for 1988 and later BB trucks.

You can see from the picture that only one of the bosses has been drilled and tapped even though there are two bosses there. The boss that is tapped is for the bypass hose. The boss that is not tapped is for a heater hose. This is the way the GM pumps for this application are set up.

Lots of info on the internet about the actual need for the bypass hose. While searching I found a guy that used the bypass circuit as heater hoses. So, you get the heater and the bypass function. This would solve my problem.

See any holes in my theory?

BB BYPASS HOSE

You can see from the picture that only one of the bosses has been drilled and tapped even though there are two bosses there. The boss that is tapped is for the bypass hose. The boss that is not tapped is for a heater hose. This is the way the GM pumps for this application are set up.

Lots of info on the internet about the actual need for the bypass hose. While searching I found a guy that used the bypass circuit as heater hoses. So, you get the heater and the bypass function. This would solve my problem.

See any holes in my theory?

BB BYPASS HOSE