Bullshark

Well-known member

I'm in the middle of upgrading my 1969 Blue Angel vert with RideTech suspension and have a question for you guys. (Hope GTR1999 chimes in).

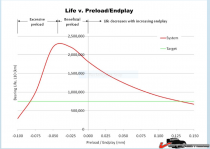

All the how-to articles recommend setting the trailing arm wheel bearing endplay to .002" max. My buddy who owns Competition Marine Center and has much experience setting up tapered bearings on off shore race boats etc. tells me that I should set them up with 7-14 inch lbs of preload. I did a little internet research and found articles like this (preload vs endplay) which tend to support his position.

So, maybe I'm poll vaulting over mouse turds here but which way is best and why?

All the how-to articles recommend setting the trailing arm wheel bearing endplay to .002" max. My buddy who owns Competition Marine Center and has much experience setting up tapered bearings on off shore race boats etc. tells me that I should set them up with 7-14 inch lbs of preload. I did a little internet research and found articles like this (preload vs endplay) which tend to support his position.

So, maybe I'm poll vaulting over mouse turds here but which way is best and why?