daveL82

Well-known member

- Joined

- Apr 10, 2008

- Messages

- 231

I built my own A-arm rear suspension with my fabricated uprights and stock C3 hub and spindles. I came across a rear C5 suspension complete less diff for $500 so I picked it up.

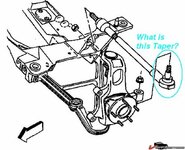

Been thinking about going with C5 spindles so need ball joint tapers to fab a-arms.

Been thinking about going with C5 spindles so need ball joint tapers to fab a-arms.