clutchdust

Millionaire Playboy

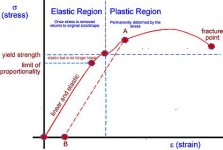

Help me out here, guys. I come here because I think this is probably the best collection of true and back yard engineers in the Corvette world so I put a lot of stock in what is said here. Most of us know the new LS platform engines use "torque to yield" bolts for all critical fasteners, like main/rod caps and head bolts. What makes, if anything, this design any better than the earlier design with a conventional torque wrench?

I would like a good explanation of the advantages to the newer method. Previously, my procedure has always been to torque all new fasteners to the torque specs to pre-stretch, then relax them and retorque to the listed torque value. I've always felt this was the best way to ensure proper long term torque values when using new fasteners. It's my understanding you can no longer do this with the "torque to yield" since they're a one-and-done fastener.

Learn me sumthin'.

I would like a good explanation of the advantages to the newer method. Previously, my procedure has always been to torque all new fasteners to the torque specs to pre-stretch, then relax them and retorque to the listed torque value. I've always felt this was the best way to ensure proper long term torque values when using new fasteners. It's my understanding you can no longer do this with the "torque to yield" since they're a one-and-done fastener.

Learn me sumthin'.