The inside edge of that reinforcement is pretty short - it's the side with the single rivet hole. I think I had my body lifted about 2" when I slid them in. I used a chunk of 6x6 on top of a floor jack to raise it up by the floor pans. Leave the bolts on one side loosely in place while tipping it. The cushion under there is about 1.5" high, so it doesn't take much to get the bracket around the mount point.

I'd replace the reinforcement on the other side while you're at it. The new ones are made from better steel, and that way you don't have to worry about hidden rust on the inside.

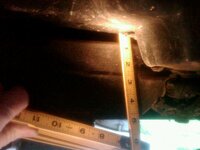

On that (driver side) mess, it looks like you're going to need to re-glass the bottom of the mount bucket and weld in a new perch. Both are seriously messed up.

I've never seen a mouse nest in the #3 hole. I wonder how it even got in there? That space is closed, unless it chewed a hole through the 'glass.