Sharkey1807

Well-known member

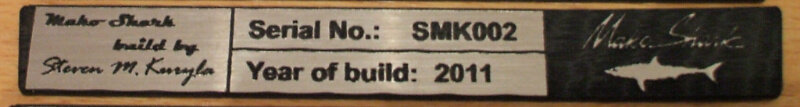

Could pick up today the new spec plates.

First was happy how they came out. Specially the small details with the signature and the Mako-Logo.

Then later at home i've realised that they guy in the lasershop didn't execute the text correctly. He did a typo in the phrase "build by", instead of "built by". Anyway have also to change the phrase "year of build" in "built in year".

No big deal while anyway the plates was cheap.

Here the batch from today not yet corrected:

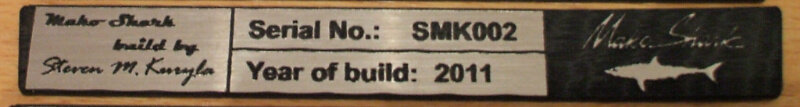

And here my spec plate, also still wrong:

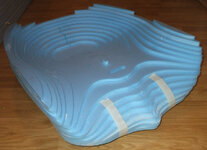

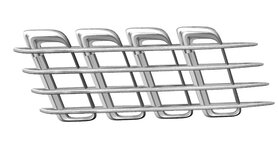

Had today also a talk with a colleague who gave me some ideas how to execute the master-seat. I will build only one seat as a Master-seat, then doing a cheap and easy to do 2pcs. mould from this.

With that i can do 2 identicall seat-shells.

After having the seat-shells in fiberglass i will screw the frame into them and fill all with light expanding foam.

He gave me also a idea how to put the Mako-Logo in the Master-seat.

Simply i will sand the Mako-script to a thickness of 1mm and then glue the Mako-shark and -script on the Master-seat. Afterwards cover all in a thick layer of clear coat.

Greetings

Robert

First was happy how they came out. Specially the small details with the signature and the Mako-Logo.

Then later at home i've realised that they guy in the lasershop didn't execute the text correctly. He did a typo in the phrase "build by", instead of "built by". Anyway have also to change the phrase "year of build" in "built in year".

No big deal while anyway the plates was cheap.

Here the batch from today not yet corrected:

And here my spec plate, also still wrong:

Had today also a talk with a colleague who gave me some ideas how to execute the master-seat. I will build only one seat as a Master-seat, then doing a cheap and easy to do 2pcs. mould from this.

With that i can do 2 identicall seat-shells.

After having the seat-shells in fiberglass i will screw the frame into them and fill all with light expanding foam.

He gave me also a idea how to put the Mako-Logo in the Master-seat.

Simply i will sand the Mako-script to a thickness of 1mm and then glue the Mako-shark and -script on the Master-seat. Afterwards cover all in a thick layer of clear coat.

Greetings

Robert