69427

The Artist formerly known as Turbo84

This is the answer I like best:

If the answer was mid to low speed then one of the following options can be used to solve the understeer:

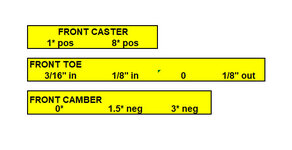

1) Increase caster angle

2) Increase front toe out

3) Reduce front ride height

4) Check tyre pressures with a gauge to ensure that the tyres are operating within recommended hot temperatures. Increase or decrease pressures accordingly.

5) Check tyre temperatures with a tyre pyrometer and make sure that the temperatures are distributed by between 10 and 15 degrees Celsius between edges with the inside being the hottest. If the inside is too hot then increase positive camber. If the outside is too hot then increase negative camber.

From your description, it sounds like the problem is more acute when the wheels are turned fairly sharply (low speed 180 at the end of a slalom) which would cause me to look at Ackermann. Do you have a situation where you have drastically increasing or decreasing Ackermann as the wheels are turned? This can be partially solved by increasing or decreasing static toe, but may hurt in other areas. I would try to duplicate the turn-in (set the wheel turn angle and ride compression/height) and check the total toe between the front wheels.

Pappy

I agree with your comments. When I first put the C4 suspension under my '69 I had a helluva bad understeer in the tight corners. After a lot of head scratching I relocated the steering rack to increase the Ackerman, and also got rid of the toe-in, and occasionally play with a touch of toe-out.