bobs77vet

Well-known member

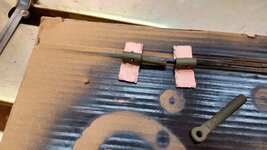

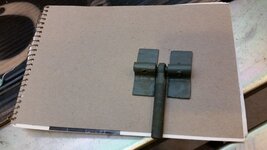

not really hard to make buffer backing plates just a grinder with a flap disc, a drill and tapping stuff. if you are so inclined heres how you do it. and use a a larger drill bit at the end to chamfer the hole that's going to be tapped.

so its cocked when I take it out

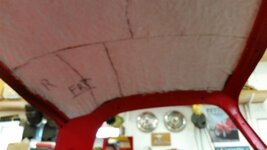

lets play around with adjusting the door fitment

add some shims

and we are getting closer.....time to quit for the day

so its cocked when I take it out

lets play around with adjusting the door fitment

add some shims

and we are getting closer.....time to quit for the day