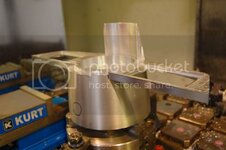

but the runny resin is a bitch to sand off compared to the composite matrix of cured resin and matte.

my other issues are, there are obiously 2 different surfaces under all that glass work, the dark looks like that's the bare glass, but large areas have what looks like that same yellow stuff under there. What is that? Evercoat gold sanding filler?

I always mask off areas around the repair, this makes sanding a lot easier. When sanding the repair, if you cut through the masking tape you know you're about to dig into the original panel and need to take it a little slower, I see nothing of that sort.

same here

I would really like to know what's going on. For instance, if you check out Stingers project, he has a ton of pics illustrating his glass work. He uses masking tape too, I do it similar, if not exactly like him. Have some pics in the 63 resto topic. No offence to heartland but this looks like "my 1st fiberglass job" I'm sure they know what they're doing but I don't understand why they do it like this. Like I said, they must love to sand???? I've seen the ZR1/C2 they did and it's amazing.