I know what kind of intake it is, it's a McFarland design. As far as I know now there's only 3 of them and this is the only one with the fuel rails. The other 2 are still brand new and come w/ the EGR adapter (I don't have that and I was outbid on the brand new one that was for sale)

I installed the booster pump. Apparently the procharger instructions tell you to screw the pump to the floor pan and to cut a fuel line and use the supplied rubber hose to plumb it in. That stuff doesn't fly for me, so I came up with this. Some adapters on the short rubber section between tank and body and using AN hardware I routed it to the pump. unfortunately the pump has hose barbs so I had to resort to hose clamps there (I hate those things) but all in all it's a lot cleaner than per the instructions. That Fays 2 sure is handy for hanging stuff off.

Humm....one side has rust behind the ground effects. No wonder, screws thread into bare steel. Probably self tappers too. More stuff to fix

Took the whole wing off because that side needs the door hinge bushed too

Thinking about going with the later GFX, the fake air ducts give it a more modern look

Didn't get to do a lot more, stripped most of the front end for spraying and fixing some minor issues.

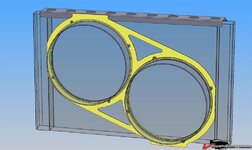

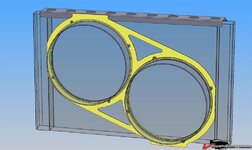

Going to install 2 Spal 12" high perf. puller fans instead of the stock dual fans, problem is I'll have to design a mounting bracket or shroud for them. More custom work to be donie.

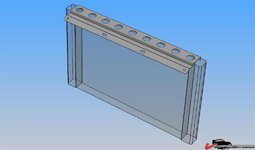

Ignore the crookedness of the radiator, that's how we receive our stuff here courtesy of UPS.

Quickly designed a neat mounting bracket. Didn't want to go with a full shroud, the fans will cool plenty as is and I don't want them to mount closer to the engine and with the fans against the core a shroud is useless. It's the yellow part in this design

Here's ver 2.0 of the rad mount, this time I can dimple die it. This version fits around the tanks, not just the core.

The fan shroud

Started putting the engine back together after finally getting the zz409 cam (stupid customs here was holding on to it for a couple of weeks). Also visible is my drain hookup for the P600B.

The stock v/flat belt combo pulleys are giving me issues, I'll either have to convert the aluminum spacer thing for the SC pulley into a pulley by having it cut or flat belt grooves or have a new one made with a wider front diameter for a larger pulley. I already have a smaller waterpump & alternator pulley.

Got the radiator all done:

Fits like a glove

Used carriage bolts, the square below the head is hammered tight into the aluminum so they won't spin

all done, these fans move a lot of air. Gale force winds LOL

Rad mount ver 2.0 now dimple died

The whole shebang installed

I also made good progress building up the engine. Cam installed and everything buttoned up/dialed in. Mounted the supercharger and made a custom little bracket since I don't have the OEM serpentine drive, it spaces the whole assembly forward about as much as the stock serpentine stuff does. Also, there's an additional hole that corresponds with where normally the bolt goes through the alternator. I'm going to add a 4th bolt & spacer to it since I still have 1 unused hole in the head and bracket. There's a small bolt in there now, adding a longer bolt & spacer only required drilling the supercharger bracket. No big deal. Also have the oiling system & return all hooked up. Going to either cut serpentine grooves in the drive spacer (alu spacer thing) or design a new one, larger diameter. Have to figure out the drive ratios first and see where my KRC pump ends up.